Premier Aluminum Llc Fundamentals Explained

Premier Aluminum Llc Fundamentals Explained

Blog Article

Premier Aluminum Llc Things To Know Before You Get This

Table of ContentsThe smart Trick of Premier Aluminum Llc That Nobody is DiscussingThe smart Trick of Premier Aluminum Llc That Nobody is DiscussingThe Best Guide To Premier Aluminum LlcThe Definitive Guide for Premier Aluminum Llc

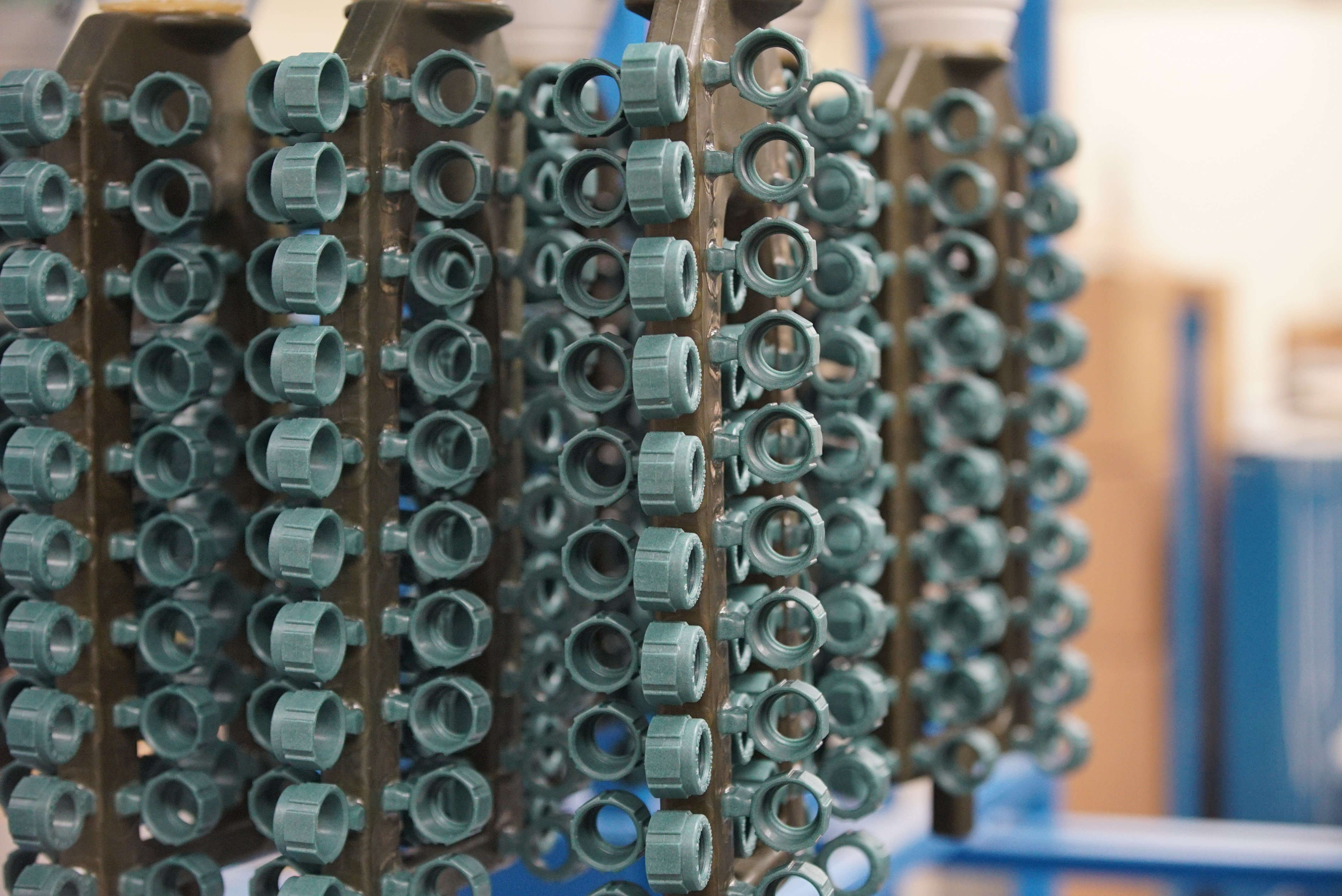

(https://pinshape.com/users/7358404-premieraluminum#prints-tab-open)Traditionally, a buyer's key duty was to locate professional and receptive vendors. In many cases, purchasers presumed that any vendor going to contractually satisfy the acquisition need was certified. Utilizing reduced expense and unqualified providers can cause high quality concerns, and lost time and money in the long run. To help you with the process, right here are some things to take into consideration when selecting the appropriate metal casting distributor.

A company that only uses the investment spreading procedure will try to market you on why that procedure is best for your application (Foundry near me). Yet suppose making use of the sand casting process is best for you and your requirements? Rather, try to find a provider that provides a variety of casting procedures so the most effective option for YOU is chosen

If dealing with a single resource for all of your casting needs is essential to you, the distributor needs to be diverse in its capabilities. When combined with other integrated capabilities, this can assist simplify and compress the supply base. When selecting the best spreading supplier, careful factor to consider ought to be provided to top quality, solution, and cost.

Excitement About Premier Aluminum Llc

Purchasers significantly choose casting vendors that have machining capabilities. This can stay clear of dispute if issues are uncovered throughout machining. If a 3rd party is machining, it might lead to "finger-pointing" about that is at fault. Is it a spreading issue or a machining issue? If the spreading provider discovers a problem during machining, the problem is dealt with much faster with no disagreement over whose fault it is.

What do you need from your casting supplier? Are you looking for a person to just provide a metal element to your front door or do you require straight from the source extra?

Others will go beyond the letter of the PO to aid you conserve time and money. Do you have requirements for both ferrous and non-ferrous alloys? Some shops are limited or specialized. Make certain the distributor can meet all your material or alloy requirements to remove the demand for multiple vendors.

The Ultimate Guide To Premier Aluminum Llc

Research study the provider's site. Talk to a sales rep or organization affiliate.

Light weight aluminum is additionally light-weight and has good corrosion resistance, making it perfect for applications where weight and sturdiness are necessary factors. In addition, light weight aluminum casting is a cost-effective technique of manufacturing, as it needs much less energy and resources than other methods. Iron casting, on the other hand, entails putting molten iron right into a mold to develop a preferred form.

Little Known Questions About Premier Aluminum Llc.

Iron spreading is also able to withstand heats, making it ideal for usage in applications such as engine components and industrial equipment. Nonetheless, iron spreading can be much more costly than light weight aluminum spreading because of the higher price of resources and the energy needed to thaw the iron. When choosing in between light weight aluminum spreading and iron casting, it is vital to think about the particular needs of the application.

In final thought, both aluminum casting and iron casting have their own special benefits and downsides. There are 3 sub-processes that fall under the classification of die casting: gravity die spreading (or permanent mold casting), low-pressure die casting and high-pressure die casting. To obtain to the ended up item, there are 3 main alloys used as die spreading material to choose from: zinc, aluminum and magnesium. Report this page